Insight

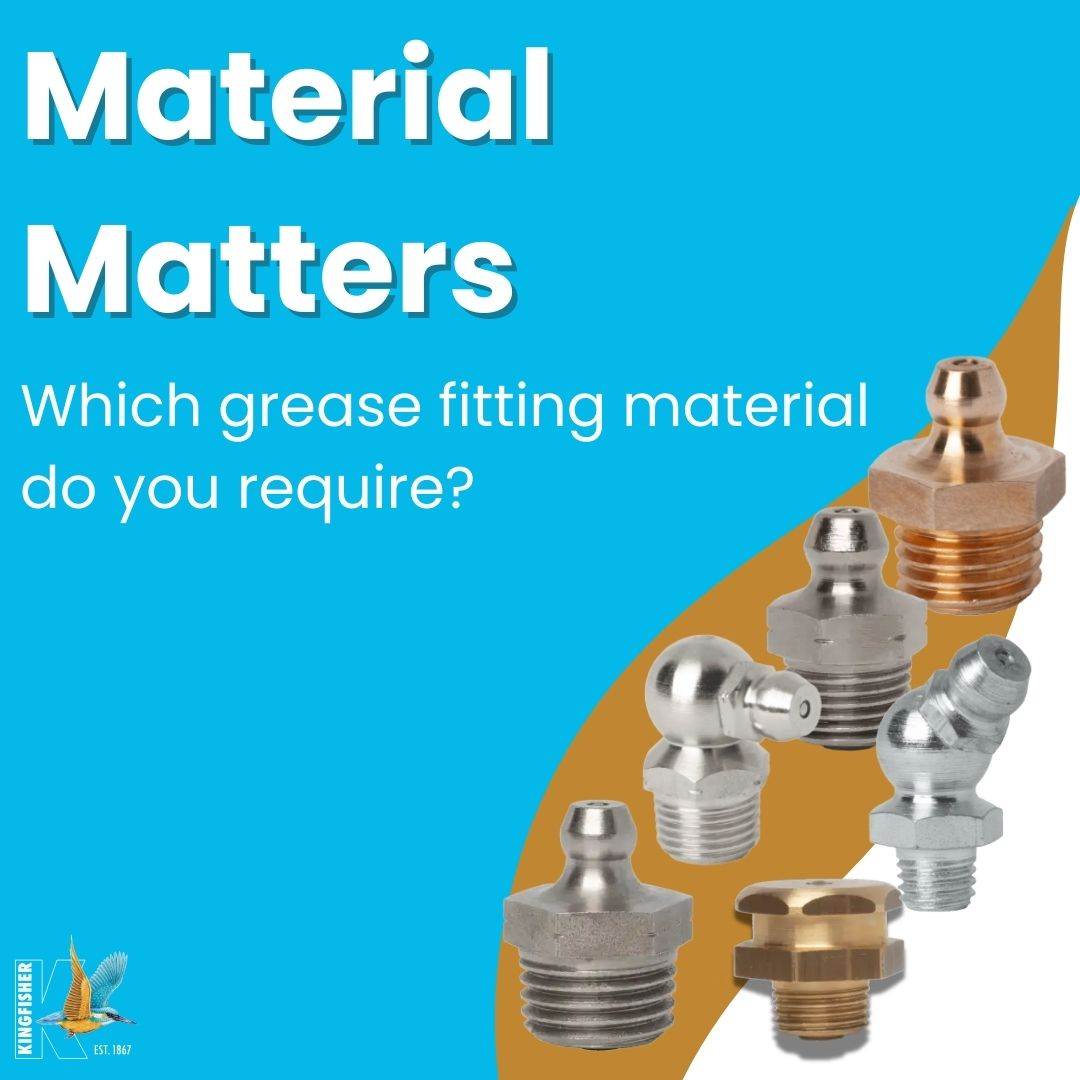

Material Matters - Choosing the Right Grease Fitting for Your Application

Not all grease fittings are created equal. The material you choose can have a big impact on performance, durability, and safety — especially in demanding environments. Here’s a simple breakdown of the materials we supply and what each is best suited for.

We have a range of versatile materials in which we manufacture grease nipples, meaning we have a solution for every application.

Steel

Best for: General-purpose applications

Steel is strong, affordable, and widely used. It handles high pressure and is ideal for most industrial settings. Zinc-plated versions offer extra corrosion protection, making them suitable for both indoor and outdoor use.

Benefits:

-

High strength

-

Cost-effective

-

Good for standard machinery

303 Stainless Steel

Best for: Outdoor and mildly corrosive environments

303 stainless provides a balance of corrosion resistance and strength. It’s often used in agricultural and construction equipment that faces the elements but not extreme chemical exposure.

Benefits:

-

Resists rust in damp conditions

-

Maintains strength and reliability

-

Easy to machine and fit

316 Stainless Steel

Best for: Harsh and corrosive environments

This is a higher-grade stainless steel with superior corrosion resistance. It’s commonly used in marine, food, and chemical industries where failure isn’t an option.

Benefits:

-

Excellent resistance to corrosion

-

Ideal for marine and washdown areas

-

Long-lasting and low maintenance

Brass

Best for: Light-duty or non-magnetic applications

Brass fittings are naturally resistant to corrosion and are non-magnetic. They’re easy to work with and a good fit for light industrial or specialist equipment.

Benefits:

-

Resists rust without coatings

-

Safe for low-pressure systems

-

Non-magnetic – useful in sensitive equipment

Monel®

Best for: Extreme environments

Monel is a high-performance alloy known for its durability. It works well in severe conditions, from offshore rigs to heavy industry, where other materials might fail.

Benefits:

-

Tough and corrosion-resistant

-

Performs under pressure

-

Trusted in marine and chemical sectors

Phosphor Bronze

Best for: High-wear and safety-critical settings

Phosphor bronze is chosen for its excellent wear resistance and non-sparking properties. It’s strong under friction and pressure, making it ideal for rail, mining, and explosive environments.

Benefits:

-

Withstands friction and heavy loads

-

Long service life

-

Non-sparking – safe in hazardous areas

Need Help Choosing?

We supply one of the UK’s most complete ranges of grease fittings — in stock, ready to ship, and backed by expert advice.

If you’re unsure which material is right for your equipment, get in touch with us. We’ll help you find the right fit first time.