Grease fitting Innovation

| About Kingfisher

Assured quality

In control of the process.

Having a comprehensive range of services in-house provides us with a high level of control and ensures that we can maintain quality throughout every stage of the process. By having control over research, design, toolmaking, heat treatment, spring manufacture, and production, we can closely monitor and manage each step to meet the desired standards.

Controlling the entire process allows us to streamline operations, optimise efficiency, and maintain consistent quality. By eliminating the need to outsource various tasks, we can also reduce potential delays and dependencies on external suppliers.

Overall, having comprehensive in-house capabilities and stringent quality control measures puts us in a favourable position to consistently deliver high-quality products or services to our customers.

Unrivalled service

In today’s competitive marketplace, it’s not enough to rely on quality.

At Kingfisher, we pride ourselves on providing unrivalled service to our valued customers. With a commitment to excellence, we go above and beyond to meet and exceed your expectations. Our highly trained and dedicated team is always ready to assist you, offering personalised solutions tailored to your specific needs. We believe in building long-lasting relationships based on trust, integrity, and reliability. From prompt response times to meticulous attention to detail, our unrivalled service ensures that every interaction with us is seamless and enjoyable. We have all the resources on hand we need to receive orders and offer a same-week service in the majority of cases.

Experience the difference with our unparalleled commitment to your satisfaction.

| Over 150 years of excellence

Our History

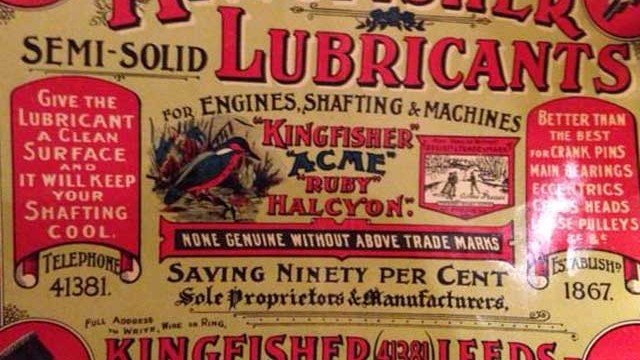

From the day that Kingfisher was founded in Leeds in 1867 we have stayed true to our founding principle of excellence in everything that we do.

It’s a very different business today to the one that first opened for business over 150 years ago, but we remain committed to quality, service and value for all of our customers.

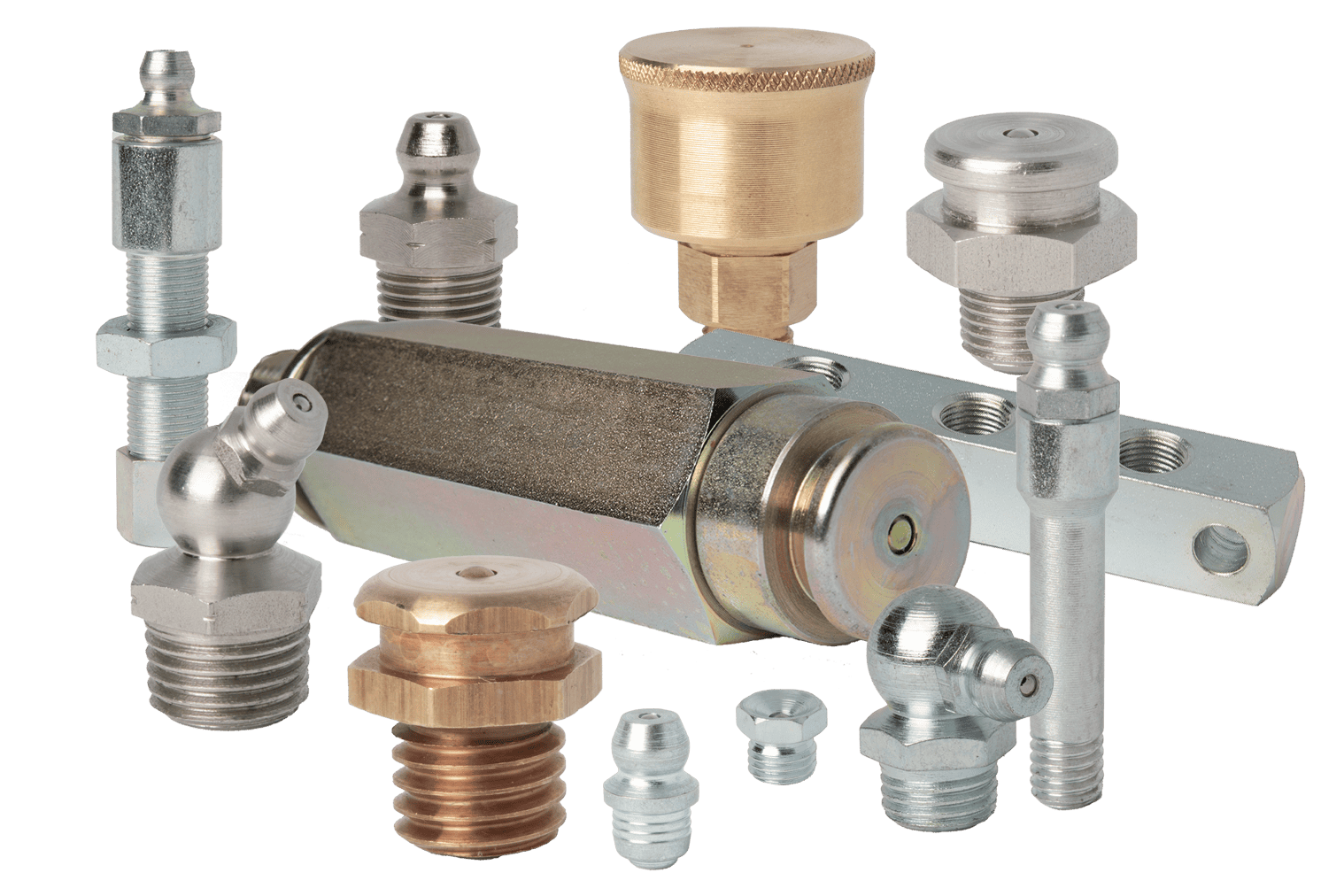

Originally a manufacturer of grease and a blender of oils, we have always maintained a responsive and innovative approach to lubrication. Through a carefully controlled program of growth and development, we have become one of the largest and most influential manufacturers of grease fittings in the world today.

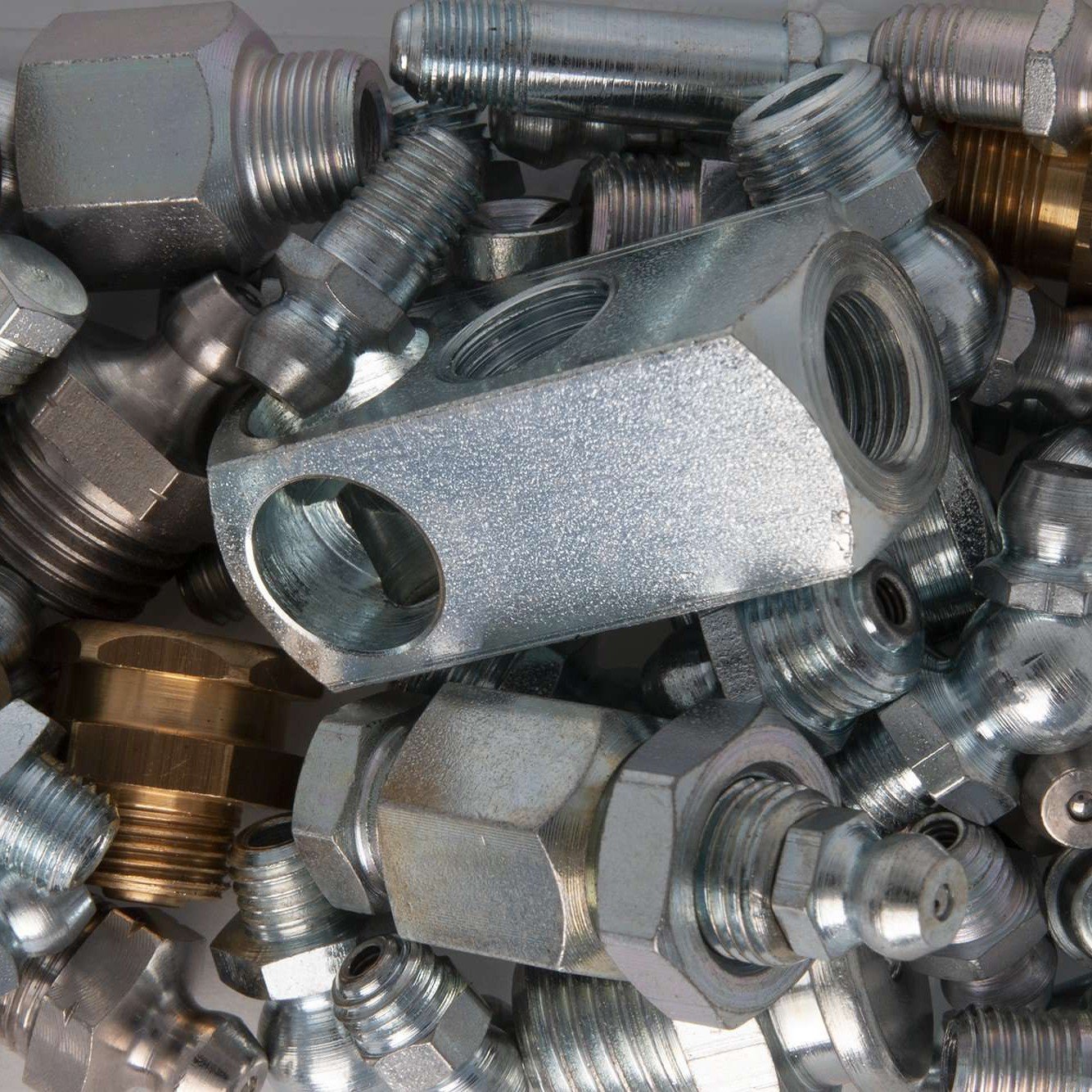

Our high-capacity factory has moved with the times and now produces state-of-the-art grease lubrication fittings that are used not just in the UK but are also exported all round the world to clients operating in many sectors.

While the focus of our business is in making bulk sales, we also take on bespoke projects with shorter production runs. With all the in-house expertise needed, as well as CNC machines to create the products, we provide a one-stop service with excellence guaranteed.

Kingfisher's Timeline

Oil blending and grease manufacture

Spring feed Lubricators

Blued Steel Screw Pressure Lubricators Grease cups also known as “stauffers”

Large Spring & Screw Lid Oilers (3/4″ to 2.1/2″)

Drop Sight Feed Oilers

Oil Level Gauges

3/8″ to 1/2″ Spring Lid Oilers

1/4″ Spring Lid Oilers

Push Type Fittings

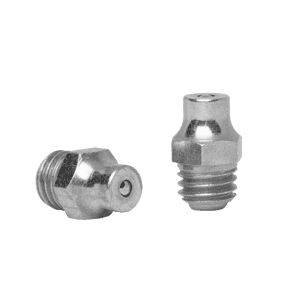

Button Head Fittings

Angle Hydraulic Grease Fittings

Straight Hydraulic Fittings

German (DIN) Self-Forming Threads

US (SAE) Self-Forming Threads

303 Stainless Steel Grease Fittings

Hex Headed Plugs

316 Stainless Steel Grease Fittings

Cup Type Lubricators

CuNi (Monel®) Hydraulic Grease Fittings

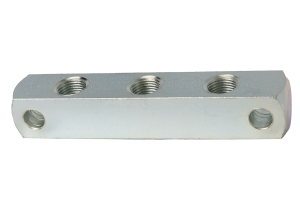

Anchor Blocks

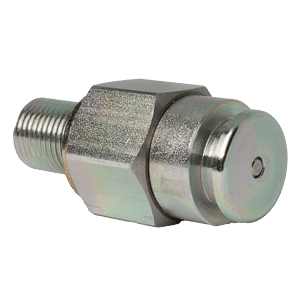

High Pressure Leak Proof Button Head

Present Push types re-introduced

Kingfisher becomes an Employee Ownership Trust Company

Kingfisher Today

An Employee Owned Company

Kingfisher are proud to be an employee-owned company. In 2020, the employee ownership formed. This creates a collective presence among our employees to all move together in the same direction to ensure the business' long-term success.

The element of shared ownership empowers our employees to embody the Kingfisher values and enables their voices to be heard through our employee-appointed board of trustees.