Independent Manufacturer’s Representative – Grease Fittings

Independent Manufacturer’s Representative – Grease Fittings

Territory: United States

Company: Kingfisher (Lubrication) Limited – UK Manufacturer

Kingfisher (Lubrication) Limited, a UK-based high-volume manufacturer of precision grease fittings (zerk fittings),

is seeking experienced independent manufacturer’s representatives in the USA to help expand our distribution

into OEMs and Tier 1 suppliers across industrial, agricultural, and heavy equipment markets.

We have a strong worldwide reputation for quality, consistency, and on-time delivery – and now we’re

looking for US-based reps to help us build on that success stateside.

Ideal Candidate Profile:

- Actively involved in the fastener, fittings, or industrial supply sector

- Established relationships with OEMs and Tier 1s in sectors like construction equipment, agriculture, automotive, or off-highway machinery

- Contacts at companies such as Caterpillar, John Deere, Dana, CNH, AGCO, or similar

- Motivated self-starter with a proven record of building a line and closing sales

What We Offer:

- A well-established, high-volume product line with a worldwide reputation for quality and reliability

- Excellent commission structure

- Full technical and sales support from our UK head office

- Opportunity to represent a trusted brand with growing US market demand

This is a 1099 / commission-only opportunity ideal for reps looking to expand their current product offering in a complementary category.

To apply or learn more:

Email: technical@kingfisherlub.co.uk

Phone: +44 113 209 8989

Website: www.kingfisherlubrication.com

Insight

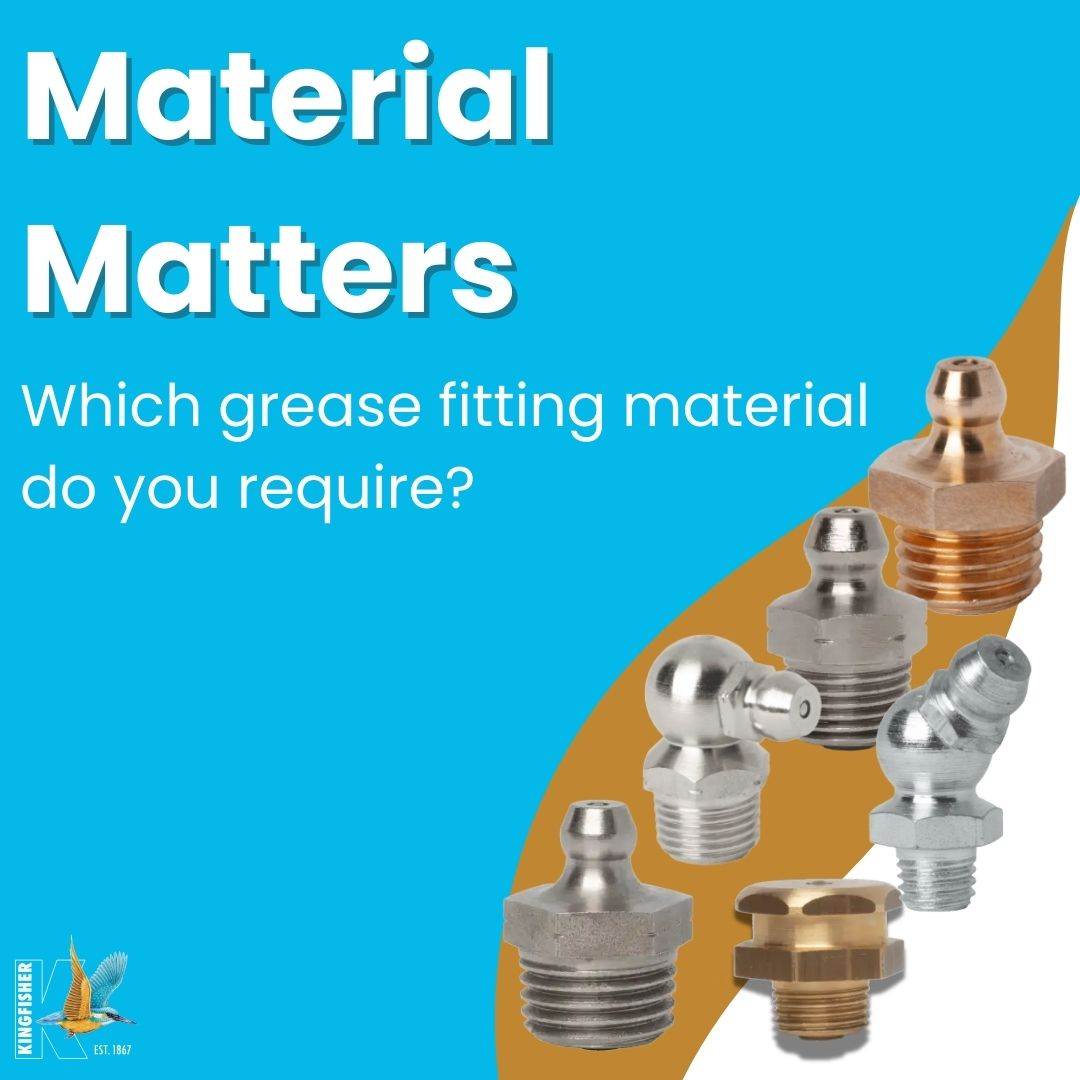

Material Matters - Choosing the Right Grease Fitting for Your Application

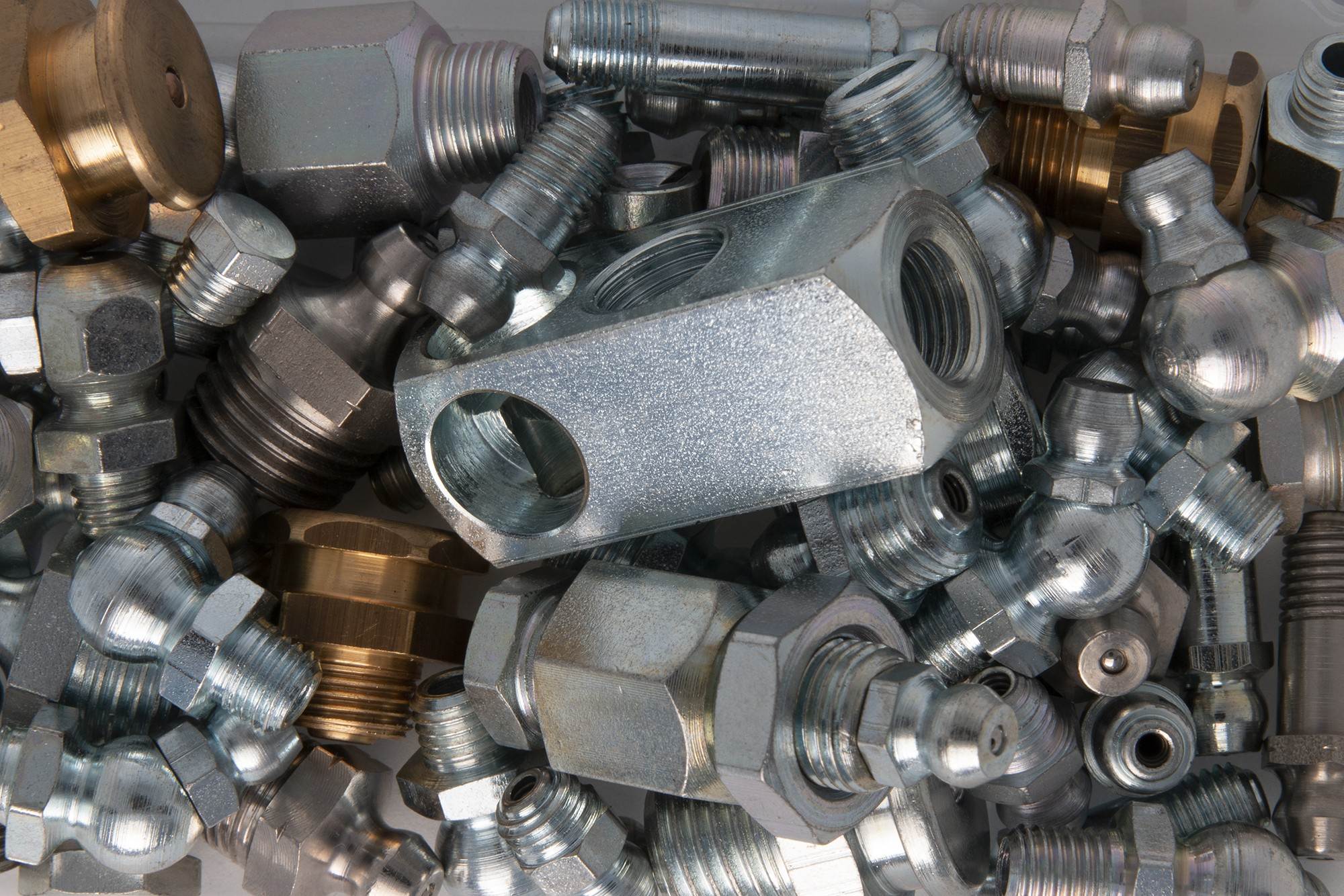

Not all grease fittings are created equal. The material you choose can have a big impact on performance, durability, and safety — especially in demanding environments. Here’s a simple breakdown of the materials we supply and what each is best suited for.

We have a range of versatile materials in which we manufacture grease nipples, meaning we have a solution for every application.

Steel

Best for: General-purpose applications

Steel is strong, affordable, and widely used. It handles high pressure and is ideal for most industrial settings. Zinc-plated versions offer extra corrosion protection, making them suitable for both indoor and outdoor use.

Benefits:

-

High strength

-

Cost-effective

-

Good for standard machinery

303 Stainless Steel

Best for: Outdoor and mildly corrosive environments

303 stainless provides a balance of corrosion resistance and strength. It’s often used in agricultural and construction equipment that faces the elements but not extreme chemical exposure.

Benefits:

-

Resists rust in damp conditions

-

Maintains strength and reliability

-

Easy to machine and fit

316 Stainless Steel

Best for: Harsh and corrosive environments

This is a higher-grade stainless steel with superior corrosion resistance. It’s commonly used in marine, food, and chemical industries where failure isn’t an option.

Benefits:

-

Excellent resistance to corrosion

-

Ideal for marine and washdown areas

-

Long-lasting and low maintenance

Brass

Best for: Light-duty or non-magnetic applications

Brass fittings are naturally resistant to corrosion and are non-magnetic. They’re easy to work with and a good fit for light industrial or specialist equipment.

Benefits:

-

Resists rust without coatings

-

Safe for low-pressure systems

-

Non-magnetic – useful in sensitive equipment

Monel®

Best for: Extreme environments

Monel is a high-performance alloy known for its durability. It works well in severe conditions, from offshore rigs to heavy industry, where other materials might fail.

Benefits:

-

Tough and corrosion-resistant

-

Performs under pressure

-

Trusted in marine and chemical sectors

Phosphor Bronze

Best for: High-wear and safety-critical settings

Phosphor bronze is chosen for its excellent wear resistance and non-sparking properties. It’s strong under friction and pressure, making it ideal for rail, mining, and explosive environments.

Benefits:

-

Withstands friction and heavy loads

-

Long service life

-

Non-sparking – safe in hazardous areas

Need Help Choosing?

We supply one of the UK’s most complete ranges of grease fittings — in stock, ready to ship, and backed by expert advice.

If you’re unsure which material is right for your equipment, get in touch with us. We’ll help you find the right fit first time.

May 9, 2025

News

Celebrating Sara and Andy: Kingfisher’s New Mental Health First Aiders

At Kingfisher (Lubrication) Limited, we pride ourselves on fostering a supportive and inclusive workplace where the well-being of our employees is a top priority. That’s why we are thrilled to celebrate the achievement of two of our team members, Sara and Andy, who have successfully completed their Mental Health First Aider (MHFA) training with St. John’s Ambulance!

Mental health is just as important as physical health, and having trained Mental Health First Aiders in the workplace ensures that colleagues have the support they need when facing challenges. Stress, anxiety, and other mental health concerns can affect anyone, and it’s crucial to create a culture where people feel safe to seek help. Sara and Andy’s dedication to completing this course demonstrates their commitment to fostering a compassionate and understanding work environment.

The MHFA training equips individuals with the knowledge and skills to recognize early signs of mental health issues, provide initial support, and guide colleagues toward professional help when necessary. This training not only benefits those facing challenges but also helps in reducing stigma and encouraging open conversations about mental well-being.

Andy White (Left) and Sara Lemm (Right) are now officially recognised and qualified as Mental Health First Aiders at Kingfisher (Lubrication) Limited.

Upholding our Employee Values

By having trained Mental Health First Aiders, Kingfisher is taking a proactive step toward ensuring that all employees feel heard, valued, and supported. Mental well-being plays a significant role in overall job satisfaction and productivity, and creating an environment where employees can thrive both personally and professionally is a shared responsibility. As an Employee Ownership Trust, this is a pivotal part of our company values – making employees feel heard and supported.

We want to extend our sincere gratitude to Sara and Andy for stepping up to this vital role. Their presence as Mental Health First Aiders means that employees now have trusted, approachable resources available whenever they need support.

Please join us in congratulating them on this fantastic achievement! Together, we can create a healthier, more supportive workplace.

February 13, 2025

Innovation

Modernising Our Manufacturing: How the Index MS24-6 Lathe Is Driving Kingfisher Lubrication Forward

In the precision manufacturing business, keeping ahead of the curve is all about adopting technology that can boost quality, efficiency, and adaptability. Here at Kingfisher (Lubrication) Limited, we’re taking an important step toward modernisation with the purchase of the Index MS24-6 multi-spindle automatic lathe, combined with the Index MBL 4.3m rack-loaded bar loader. This new machinery enhances our current capabilities and positions us perfectly to expand into new markets and develop additional product lines.

Here is how this exciting investment will enable us to adopt more efficient and advanced manufacturing operations.

Efficiency Improvement in Grease Fitting Production

The Index MS24-6 multi-spindle lathe provide us with increased capability and capacity of high-precision, high-reliability grease fitting production. Allowing simultaneous machining of a number of spindles, we see a dramatic reduction in cycle times when compared to using a single-spindle lathe. The increase in speed allows for the production of more units in less time and is, therefore, a key output of meeting high demand or tight deadlines without compromising on quality.

The MBL 4.3m rack-loaded bar loader adds another level of efficiency by automating the long bars’ loading and cutting down manual work. This saves our skilled machinists a lot of time, which is dedicated to controlling quality, and simultaneously allows us to run more smoothly and consistently throughout the day. Coupled with the lathe, the bar feeder is driving up our throughput while keeping quality at the centre of our manufacturing processes.

The Index MS24-6 Lathe is the latest addition to the machine shop at Kingfisher.

Ensuring Consistent Quality

The MS24-6 will bring even greater consistency to our production; with multiple spindles working in tandem, we can eliminate transferring components from one machine to another, reducing the possibility of errors or defects. Each spindle can perform different operations, meaning we can produce fully finished components in one run.

This allows us to meet our high-quality standards for grease fittings while further strengthening our reputation for reliability.

For us, a reputation for excellence is a must, particularly in industries, like aerospace and agriculture, where fitted products are required to be very precise and durable. The Index MS24-6, with features such as high-precision tool holders and advanced control systems, enables us to produce the kind of high-quality products our customers rely on with even greater accuracy and precision.

Meeting Customer Needs Faster Through Reduced Lead Times

With the shorter cycle times and automated material loading, we aim to reduce the lead times of manufacturing grease fittings. We pride ourselves on being able to deliver a high-quality product quickly to our loyal customers. However, this addition to our machine shop strengthens our ability to do so. This way, we are able to satisfy the demand of our customers quicker and build stronger, more longer-lasting relationships. It means we can also handle bigger orders without affecting the turnaround time, keeping our customers happy and strengthening our partnerships moving forward.

Inside the Index MS24-6.

Exploring New Markets with a Versatile Tool

While the MS24-6 is ideal for grease fittings, it’s also versatile enough to produce a wide range of precision components. With this flexibility, we’re now able to explore additional product lines and look at entering industries such as aerospace, agriculture, and transportation, all of which require high-quality, precision-manufactured parts.

Future-Proofing Our Manufacturing

Investing in the latest manufacturing technology isn’t just about immediate benefits; it’s about setting ourselves up for the future. The Index MS24-6 gives us the flexibility to integrate future upgrades and adapt as market demands change. This equipment is a valuable part of our long-term strategy to stay competitive, agile, and ready to grow. In summary, the Index MS24-6 multi-spindle lathe, combined with the MBL 4.3m bar loader on our shop floor, is bridging Kingfisher into a new era. It adds efficiency, further tightens quality control, and opens up possibilities for diversification into new and existing markets. In the coming years of growth, this modernisation will be one of the key initiatives that will help us take care of business, open new opportunities, and forge lasting success with our customers.

View our full range of grease fittings and lubrication components here.

December 6, 2024

Kingfisher Lubrication joins the West Yorkshire Fair Work Charter

As a business located within the West Yorkshire area, we are proud to be recognised by acceptance to the West Yorkshire Fair Work Charter (WYFWC). Employing talent and skilled personnel from the local community near our premises in Leeds has always been a major part of our business culture. The ingenuity and skills of our local community have been the heart and centre of a story lasting longer than 150 years and one that continues to strive with the new chapters we are continuing to write today.

What is the West Yorkshire Fair Work Charter?

The WYFWC is an initiative launched by the Mayor of West Yorkshire, Tracy Brabin, designed to promote and support the great employers across the county. The Charter focuses on encouraging employers within our region to foster fair working standards and provide the best possible benefits for employees within their organisations. Introducing fair working conditions promotes a positive working environment – boosting productivity and morale.

Within the charter there are five pillars, focused on how businesses can become fair employers:

- Opportunity

- Security

- Wellbeing

- Employee Voice

- Fulfilment

How do we fulfil these pillars within our organisation?

Opportunities

According to business need, we try to create the best possible opportunities for our employees. We aim to adopt a culture where we promote from within and provide training to aid progression and succession within our organisation. All employees within our organisation are encouraged to ask to learn new things as we look to better the security of our business and the abilities of our workforce.

In addition to promoting a culture of succession and progression, as we grow as a business, there are times when we must hire externally to recruit new skills and impetus. We aim to offer great opportunities to work for our organisation in the local community when required.

Security

Employees have working rights within the UK by law. As a forward-thinking organisation, we aim to uphold our legal obligations as an employer within the UK but also go the further mile to give our staff the best possible working conditions and terms of employment.

We are a National Living Wage Employer and aim to offer all employees better terms of payment where possible. In addition, we have a series of policies and procedures in place within the business to promote the security and safety of employees of Kingfisher Lubrication. As an employee ownership trust, creating a great place to work with great terms and conditions of employment is central to our business goals and some of our successes.

Fulfilment

Work should be a place where employees feel satisfied and connected with the common purpose and goals of the business. As an Employee Ownership Trust, our employees are at the foothold of the business purpose and values.

During the formation of the trust, employees were the decision-makers in forming a set of values which they believed matched the business purpose and what Kingfisher Lubrication stands for. With a set of employee-driven values, our purpose resonates with our employees.

We also aim to increase the satisfaction of our employees with appropriate opportunities to learn and develop.

Employee Voice

The voice of our employees is core to the business. Being an Employee Ownership Trust, we place immense value on the thoughts and recommendations of employees to improve Kingfisher Lubrication as we continue to grow and adopt innovations. As a leading manufacturer of grease fittings, the knowledge and intuition of our employees are invaluable to our continued success.

We want all our employees to feel heard. That’s why our trustee directors are always available for our employees with any concerns or problems they may face. The thoughts of our employees are held in the greatest regard as we all strive to do the best for our company.

Wellbeing

We want all of our employees to live happy and healthy lives. Wellbeing at work is paramount to this. Whilst we want to maximise efficiency in our operations, the physical and mental health of our employees cannot be sacrificed to achieve it. With initiatives like a four-day week and our Employee Assistance Programme, we aim to give employees the best possible work-life balance and support for their health.

We aim to promote positive mental health, but we know that this is not always possible. As a result, we have designated mental health first aiders within the organisation who are always open and available for employees to speak to if they are struggling with mental health or other issues.

Kingfisher Lubrication being included within the WYFWC is an important milestone for the business as we seek to create the best work environment for our employees.

July 2, 2024