Innovation

Modernising Our Manufacturing: How the Index MS24-6 Lathe Is Driving Kingfisher Lubrication Forward

In the precision manufacturing business, keeping ahead of the curve is all about adopting technology that can boost quality, efficiency, and adaptability. Here at Kingfisher (Lubrication) Limited, we’re taking an important step toward modernisation with the purchase of the Index MS24-6 multi-spindle automatic lathe, combined with the Index MBL 4.3m rack-loaded bar loader. This new machinery enhances our current capabilities and positions us perfectly to expand into new markets and develop additional product lines.

Here is how this exciting investment will enable us to adopt more efficient and advanced manufacturing operations.

Efficiency Improvement in Grease Fitting Production

The Index MS24-6 multi-spindle lathe provide us with increased capability and capacity of high-precision, high-reliability grease fitting production. Allowing simultaneous machining of a number of spindles, we see a dramatic reduction in cycle times when compared to using a single-spindle lathe. The increase in speed allows for the production of more units in less time and is, therefore, a key output of meeting high demand or tight deadlines without compromising on quality.

The MBL 4.3m rack-loaded bar loader adds another level of efficiency by automating the long bars’ loading and cutting down manual work. This saves our skilled machinists a lot of time, which is dedicated to controlling quality, and simultaneously allows us to run more smoothly and consistently throughout the day. Coupled with the lathe, the bar feeder is driving up our throughput while keeping quality at the centre of our manufacturing processes.

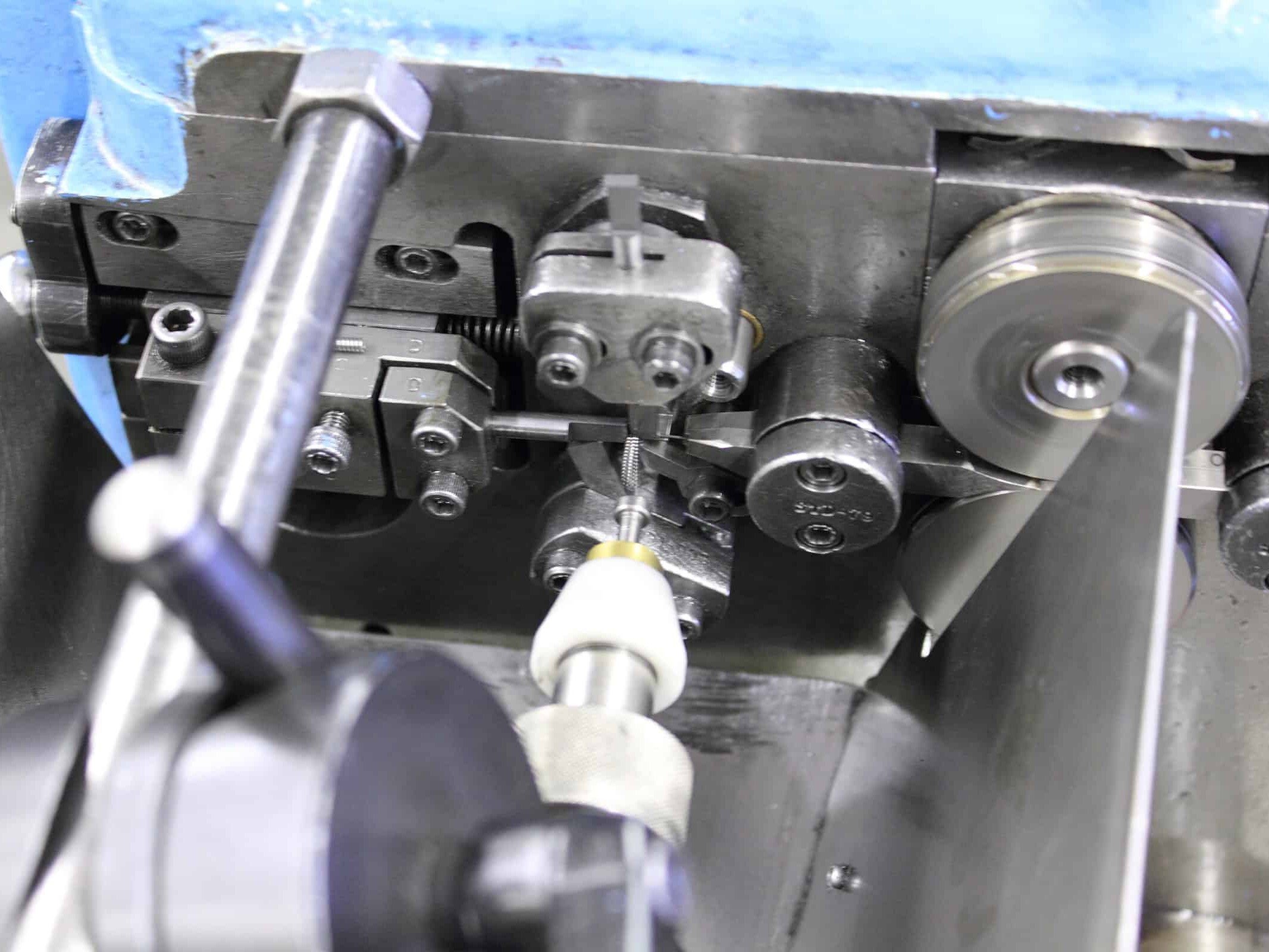

The Index MS24-6 Lathe is the latest addition to the machine shop at Kingfisher.

Ensuring Consistent Quality

The MS24-6 will bring even greater consistency to our production; with multiple spindles working in tandem, we can eliminate transferring components from one machine to another, reducing the possibility of errors or defects. Each spindle can perform different operations, meaning we can produce fully finished components in one run.

This allows us to meet our high-quality standards for grease fittings while further strengthening our reputation for reliability.

For us, a reputation for excellence is a must, particularly in industries, like aerospace and agriculture, where fitted products are required to be very precise and durable. The Index MS24-6, with features such as high-precision tool holders and advanced control systems, enables us to produce the kind of high-quality products our customers rely on with even greater accuracy and precision.

Meeting Customer Needs Faster Through Reduced Lead Times

With the shorter cycle times and automated material loading, we aim to reduce the lead times of manufacturing grease fittings. We pride ourselves on being able to deliver a high-quality product quickly to our loyal customers. However, this addition to our machine shop strengthens our ability to do so. This way, we are able to satisfy the demand of our customers quicker and build stronger, more longer-lasting relationships. It means we can also handle bigger orders without affecting the turnaround time, keeping our customers happy and strengthening our partnerships moving forward.

Inside the Index MS24-6.

Exploring New Markets with a Versatile Tool

While the MS24-6 is ideal for grease fittings, it’s also versatile enough to produce a wide range of precision components. With this flexibility, we’re now able to explore additional product lines and look at entering industries such as aerospace, agriculture, and transportation, all of which require high-quality, precision-manufactured parts.

Future-Proofing Our Manufacturing

Investing in the latest manufacturing technology isn’t just about immediate benefits; it’s about setting ourselves up for the future. The Index MS24-6 gives us the flexibility to integrate future upgrades and adapt as market demands change. This equipment is a valuable part of our long-term strategy to stay competitive, agile, and ready to grow. In summary, the Index MS24-6 multi-spindle lathe, combined with the MBL 4.3m bar loader on our shop floor, is bridging Kingfisher into a new era. It adds efficiency, further tightens quality control, and opens up possibilities for diversification into new and existing markets. In the coming years of growth, this modernisation will be one of the key initiatives that will help us take care of business, open new opportunities, and forge lasting success with our customers.

View our full range of grease fittings and lubrication components here.

December 6, 2024

Kingfisher Lubrication - Your Trusted Supplier of Grease Fittings

Quality

Kingfisher Lubrication - Your Trusted Supplier of Grease Fittings

The Importance of Grease Fittings

Grease fittings, often overlooked, are indispensable to the maintenance of mechanical systems. They facilitate the easy application of lubricants, ensuring that machinery operates efficiently and with minimal wear and tear. Without these components, the lifespan of equipment can be drastically reduced, leading to increased downtime, higher maintenance costs, and, ultimately, lost revenue.

Industries ranging from automotive to agriculture, aviation to manufacturing, all rely on grease fittings to keep their operations running smoothly. When these components are in short supply or of substandard quality, the consequences can be severe.

Competitors Leaving the Market: A Growing Concern for Customers

In recent times, several prominent manufacturers of grease fittings have withdrawn from the market. This has created a ripple effect, causing disruptions in supply chains and leaving customers scrambling for alternatives. The reasons behind these exits vary, from economic challenges to shifts in business focus, but the result is the same – customers are left with a struggle to find new suppliers.

This situation has highlighted the importance of partnering with a manufacturer that not only delivers high-quality products but also remains steadfast in their commitment to customers, even when the going gets tough.

Why Can You Trust Kingfisher Lubrication?

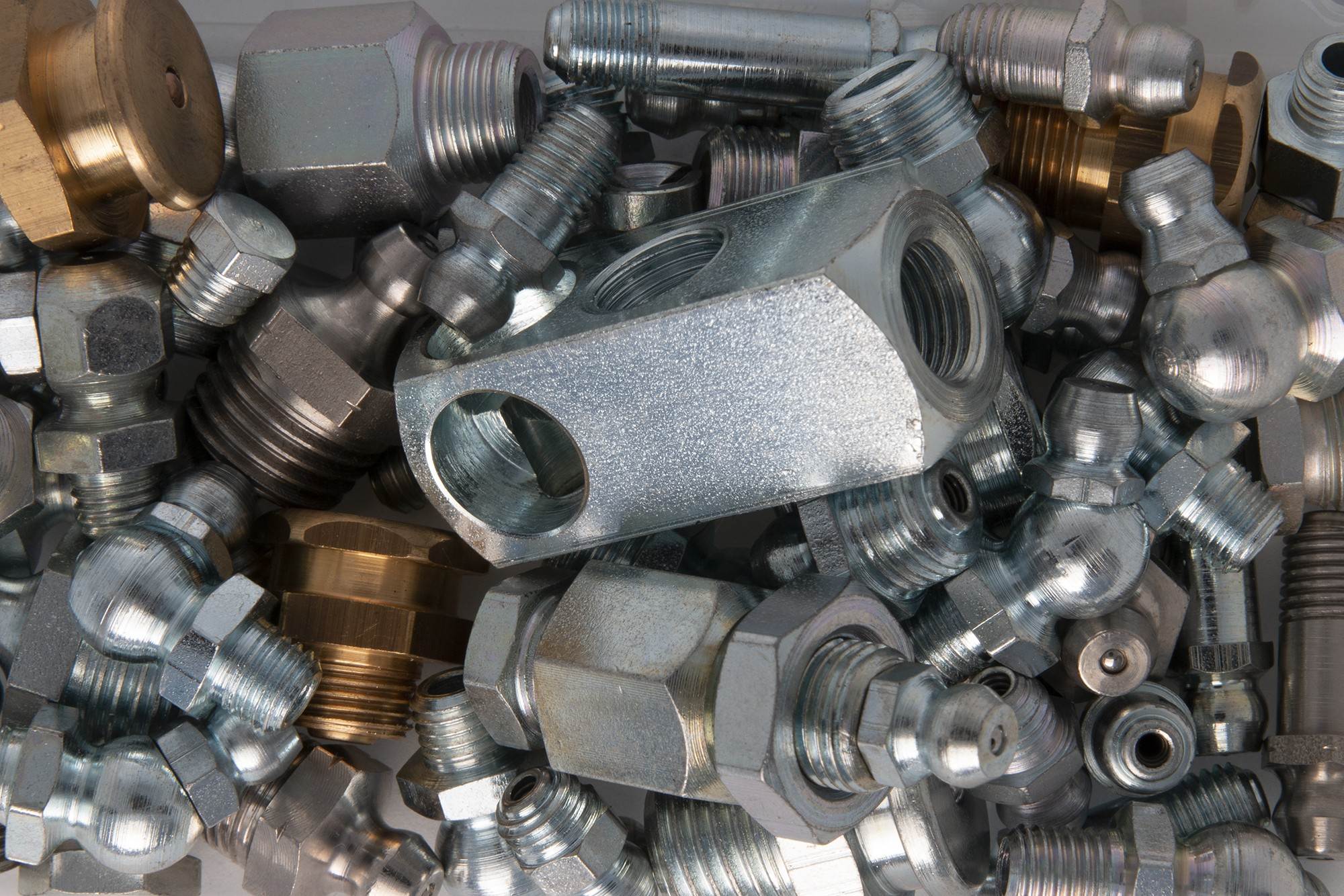

Grease Fittings are a vital part of the maintenance of machinery and mechanical systems including vehicles.

Amidst the turbulence in the market, at Kingfisher, we are still actively producing quality grease fittings for customers across various industries where grease nipples are a crucial component. If you were to trust Kingfisher as your new supplier, we can promise the following comprehensive range of benefits:

- Uncompromising Quality

Quality is the pinnacle of our success. By adhering to stringent quality control measures and continuously investing in research and development, we ensure that every grease fitting produced meets the high standards of our dedicated customer base. This commitment to excellence not only extends the life of machinery but also enhances overall operational efficiency, giving customers the peace of mind they need.

- Consistent Supply Chains

While others have faltered, we continue to maintain robust supply chains, ensuring that our products are available when and where customers need them to the best of our abilities. By building strong relationships with our suppliers and investing in reliable logistic partners, our aim is to minimise the risk of disruptions. This consistency can be a lifeline for many businesses that cannot afford downtime due to a disrupted supply chain.

- Customer-Centric Approach

Understanding the pressures our customers face, we place a strong emphasis on customer service. From offering technical support to end-to-end communication throughout the sales process, our dedicated customer service and technical teams go above and beyond to meet our customers’ needs. This customer-centric approach is centred around reliability and trust and building long-term relationships with our loyal customers.

- Adaptability and Innovation

In a market that is constantly changing, adaptability is key. We aim to demonstrate a keen ability to adapt to new trends and requirements, whether it is through the development of new products, working with customers to create a tailored solution for their systems or the adoption of more sustainable and innovative manufacturing practices. Our commitment to innovation ensures that we don’t only meet the current demands of our customers but are also prepared for future challenges.

We have over 150 years of experience in the Lubrication and Grease Fittings industry.

A Trusted Partner for the Future

As the industrial landscape continues to evolve, the need for reliable partners becomes even more critical. For businesses that depend on grease fittings, finding a manufacturer that can deliver consistent quality and support is essential to maintaining operations and staying competitive. We believe that we can be that solution provider for your business with key market players letting their loyal customers down.

Our company ethos of resilience, commitment to quality, and customer-focused approach makes Kingfisher Lubrication not just a supplier, but a true partner in success. While others have retreated, we have stepped up, proving that reliability and quality are not just buzzwords but core principles of what we do.

For businesses feeling the strain of an unpredictable market, we aim to offer the stability and assurance needed to move forward with confidence knowing they are receiving market-leading quality grease nipples. In a time of uncertainty, you can trust Kingfisher Lubrication.

View our full product range here. Want to stay updated with the latest news from Kingfisher Lubrication? Follow us on LinkedIn.

Proud to be British - Kingfisher Lubrication join Made in Britain

As a manufacturer within the UK, we are proud to announce we have been awarded the Made in Britain® Trademark. Being recognised as the sole manufacturer of grease fittings within Britain is something we take pride in and embody as part of our everyday communications in both national and international markets.

UK manufacturing and engineering continues to be one of the highest growing industries. As a British manufacturer, we are pleased to be a part of this push for growth and want to be a standard bearer within Lubrication manufacturing in the UK.

What does being a British manufacturer mean?

Kingfisher Lubrication are based in Leeds, West Yorkshire. In Leeds and across the UK, there are superb manufacturing companies who all share this badge of being Made in Britain. As one of their newest members, we are proud to be continuing this commitment and embodying being British as a wider part of our brand identity.

In international and local markets, being a British manufacturer holds value. Research from Barclays Corporate Banking shows that 39% of international consumers are more likely to purchase a product if it is British as it perceives quality. At Kingfisher, we pride ourselves on providing our customers industry-leading quality and the Made in Britain mark aims to promote quality manufacturing in the UK – making the membership a great representation for us as a business.

Driven by our values

When Kingfisher became an Employee Ownership Trust in 2020, collectively all our employees decided on a set of six core values to embody who we are and what we do. Two of the values decided by our staff were ‘British’ and ‘Quality’.

Being British is a major part of the company’s identity and history. Kingfisher have a 157-year long affinity with UK manufacturing and since establishment we have had a major presence as a recognised employer of local talent and supplier of high-quality products in Leeds and across the country.

In addition, within the local and international landscape of manufacturing, being a British manufacturer exudes a high-level of quality. ‘Quality’ was nominated as one of our company values as that’s what we do – our dedicated and highly proficient workforce take pride in consistently delivering the finest grease fittings and lubrication components the industry has to offer.

Therefore, with Made in Britain’s purpose being to promote quality manufacturing within Britain, we feel that the trademark fits perfectly with our company values. Learn more about our company values here.

March 13, 2024

Sustainability

Sustainable Innovations: Solar Panels

It has been a monumental few months at Kingfisher as far as innovation is concerned. In addition to the arrival of our brand-new Index MS22 machine, we have had solar panels installed in recent months.

As a manufacturing business in Leeds, our green and sustainability credentials are massively important to us and present a major opportunity to establish ourselves as a leader in sustainable manufacturing within our market. That is why we have taken steps, like installing solar panels, to reduce our carbon footprint and improve our energy efficiency by adopting renewable energy

What will Solar Panels provide for Kingfisher?

In partnership with Heatsource Direct, we were able to install a high-quality solar system which has been built to last. Not only have we future-proofed with a new major energy source for our business; we have taken advantage of the opportunity to reduce our carbon output by operating with renewable energy generation.

Longer-term – the solar panels will make our manufacturing processes more efficient and cost-effective with less non-renewable energy required to power our intensive line of manufacturing machinery. Eventually, this will enable us to pass on these reduced manufacturing costs to our loyal customers due to our reduced energy usage.

Helen Thornley, Financial Director at Kingfisher Lubrication, said: “We’re well aware of the need for the manufacturing industry to lower its carbon footprint and we have been working hard to bring down our emissions where we can, with solar energy high on our green wish list. So, to have completed this project and improve our sustainability credentials is really pleasing.”

This innovation would not have been possible without the support and expertise of the team at Heatsource Direct. If you would like to find out more about their offerings, you can visit their website here.

How much energy will we save?

In the peak summer months, when we experience the joys of the Great British summertime, we will be able to generate enough energy from the sun to power up to 30% of our manufacturing efforts. This is a major boost for us as a business, as we make a concerted effort to increase our efficiency and reduce our wastage within the way we manufacture our products. Not to forget, this has major cost-saving benefits with the astronomical rises of energy in recent months.

Sustainability at Kingfisher

We pride ourselves on adopting sustainable processes within our business. The need for sustainability within the manufacturing industry is paramount and our eventual goal is to be an industry leader in the adoption of green processes. We have already taken key major steps, like installing solar panels, on our journey to be a sustainable manufacturer but we are also aware of how much work there is left to do for us as a business and the industry as a whole.

Some of the other sustainable initiatives we have adopted to date include:

– Recycling up to 92% of our manufacturing waste

– Installation of energy-efficient LED lighting across our manufacturing and office spaces

– Innovation and streamlining of internal processes with the ultimate goal of being paper-free

You can find out more information about our commitment to sustainability on our environmental policy page here.

February 14, 2024

News

The Story Behind The Saints Row Mural

Leeds is home to many artistic and visual spectacles, including possessing its own art gallery. In 2022, Kingfisher Lubrication became home to one of the city’s newest and most eye-catching works of art as part of the launch of a brand new video game.

A target of Vandalism

The exterior wall of the Kingfisher Lubrication building, backing onto Sackville Street, was previously a target of vandalism. Covered in graffiti and creating an eyesore for passers-by of the Kingfisher premises, we believed that the wall could be put to good use for something creative that truly represented what we stand for as a business within the wider Leeds community.

The proposal dedicated for a mural alongside the launch of the new Saints Row relaunch in 2022 did just that.

Plaion / THQ / Deep Silver. | Image credit: Plaion / THQ / Deep Silver

The “Boss Factory” mural inspired by the launch of the 2022 reboot was created by street artist Captain Kris.

Leeds – “The Boss Factory”

Plaion, the game developer and creators of the Saints Row game which launched in 2022, commissioned some research to find out which city within the UK was the embodiment of entrepreneurialism among young people. The research targeted at 18 – 30-year-olds revealed that Leeds was the epitome of entrepreneurship as the most entrepreneurial city in the United Kingdom.

The free-world simulator, Saints Row, is all about being your own boss. Hence why the correlation between the most entrepreneurial city in the UK and the game made a perfect destination for such a mural. When approached about using the exterior wall of our site for the mural, we at Kingfisher jumped at the opportunity as we believe that the freedom to be creative and innovative as an entrepreneur correlate directly with our business values as an employee-ownership trust.

Plaion / THQ / Deep Silver. | Image credit: Plaion / THQ / Deep Silver

A new artistic addition to the UK's most entrepreneurial city

The mural, which a year on still sits on the side of our manufacturing premises, has become a mini tourist attraction within the Meanwood area of Leeds. Many people can be seen stopping to take a picture of the wall art.

Whilst the launch of Saints Row is now finished, we are still proud to have such an embodiment of our city's title as the "most-ambitious" city attached to our business. Want to learn more about Kingfisher Lubrication? You can view our story here.

October 19, 2023