News

The Story Behind The Saints Row Mural

Leeds is home to many artistic and visual spectacles, including possessing its own art gallery. In 2022, Kingfisher Lubrication became home to one of the city’s newest and most eye-catching works of art as part of the launch of a brand new video game.

A target of Vandalism

The exterior wall of the Kingfisher Lubrication building, backing onto Sackville Street, was previously a target of vandalism. Covered in graffiti and creating an eyesore for passers-by of the Kingfisher premises, we believed that the wall could be put to good use for something creative that truly represented what we stand for as a business within the wider Leeds community.

The proposal dedicated for a mural alongside the launch of the new Saints Row relaunch in 2022 did just that.

Plaion / THQ / Deep Silver. | Image credit: Plaion / THQ / Deep Silver

The “Boss Factory” mural inspired by the launch of the 2022 reboot was created by street artist Captain Kris.

Leeds – “The Boss Factory”

Plaion, the game developer and creators of the Saints Row game which launched in 2022, commissioned some research to find out which city within the UK was the embodiment of entrepreneurialism among young people. The research targeted at 18 – 30-year-olds revealed that Leeds was the epitome of entrepreneurship as the most entrepreneurial city in the United Kingdom.

The free-world simulator, Saints Row, is all about being your own boss. Hence why the correlation between the most entrepreneurial city in the UK and the game made a perfect destination for such a mural. When approached about using the exterior wall of our site for the mural, we at Kingfisher jumped at the opportunity as we believe that the freedom to be creative and innovative as an entrepreneur correlate directly with our business values as an employee-ownership trust.

Plaion / THQ / Deep Silver. | Image credit: Plaion / THQ / Deep Silver

A new artistic addition to the UK's most entrepreneurial city

The mural, which a year on still sits on the side of our manufacturing premises, has become a mini tourist attraction within the Meanwood area of Leeds. Many people can be seen stopping to take a picture of the wall art.

Whilst the launch of Saints Row is now finished, we are still proud to have such an embodiment of our city's title as the "most-ambitious" city attached to our business. Want to learn more about Kingfisher Lubrication? You can view our story here.

October 19, 2023

Report on ¼ x 28 Special Taper Grease Fittings

Report on ¼ x 28 Special Taper Grease Fittings

Kingfisher obtained 3 competitors’ samples of ¼ x 28 special taper grease fittings. These fittings appear to have been cold forged (as opposed to machined) and as such have rounded corners on the hexagon and a concave ball check face.

As the corners of the hexagon were rounded and not formed properly, it was difficult to measure the hexagon dimensions. The rounded corners may prove detrimental when using a socket to screw in the fitting. Most sockets and spanners rely on the corner part of the hexagon to screw them in.

The threads are rolled (not cut) which produces a slight undercut at the top of the thread. The fittings supplied had a shank diameter of 0.248″-0.249″.

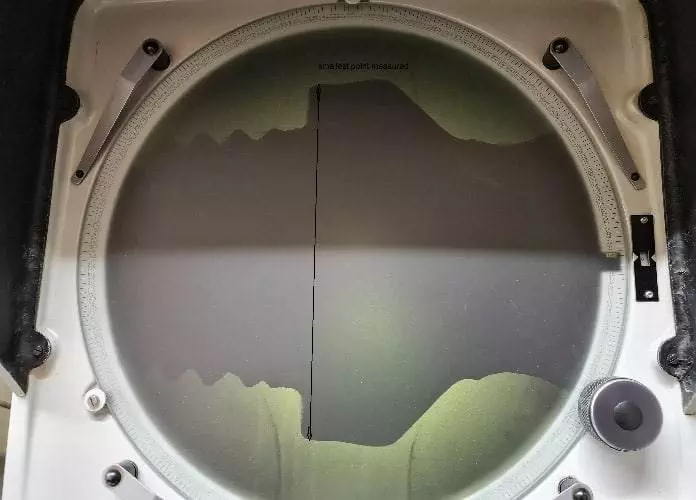

Picture showing concave ball check face, also there is a score mark on side of the head which appears to have been caused during manufacture as the plating is undamaged. The ball check face should be flat to reduce the build up of contaminants on this surface which may get introduced into the fitting during greasing.

Also of note is the yellow colour of the plating has rubbed off on exposed surfaces.

The fittings have been hardened to 85-88 HR15N, but the lip appears to have been subsequently softened to make it easier to fold over to retain the spring. (The end of the fitting is discouloured suggesting heat has been applied) This could also soften the first threads which could affect the fittings’ ability to start forming a thread in a hole.

The fittings were grease tested, the opening pressures were 60, 70 and 240psi which is a wide range indicating inconsistent manufacture and 60/70psi is rather low for a hydraulic fitting.

The fittings passed the leakage test specified in SAE J534.

When the fittings were high-pressure grease tested at 8,000psi (which is the pressure that Kingfisher test at) both springs collapsed. This is a critical failure.

The other fitting was high-pressure tested to 5,000psi as per SAE J534. The spring also collapsed.

Picture of the grease fittings after high pressure testing showing the that the balls haven’t re-seated, the 2 fittings on the left were tested at 8000psi and the one on the right was tested at 5000psi.

Report on Imported Grease Fittings

Kingfishers' findings on Imported Grease Fittings

Samples were obtained of imported grease fittings which are being offered as a cheaper alternative to Kingfisher. These parts (1/8” x 28 BSP Straight) were examined and the following was found:-

- The parts were not hardened. They should be case hardened.

- Some of the threads were very slack in the 1/8×28 BSPF no/go gauge. This may lead to leakage around the threads.

- The flank angle of the thread was 60°-65° (it should be 55°)

- The shank length compared with DIN71412 was too short at 4.5mm (it should be 5.0-5.5mm)

- The lip was too long compared with DIN71412 at over 1mm (it should be less than 0.7mm)

- The edges of the parts look very rounded as if they have been in acid for a long time (possibly as when they were cleaned as part of the plating process)

When 2 parts were grease tested it was found that the opening pressure which was initially 230psi and 160psi dropped to 150psi and 60psi. After a high-pressure test at 8000psi, a large drop like this could indicate that the spring may fail with repeated use.

When the 2 parts were leak tested at 5000psi, one leaked all its grease past the ball. The other part leaked out of the neck! When this part was sectioned, it was found that, although the ball check was central, the internal drilling was very off centre and the neck wall was very thin and had cracked.

This failure could result in serious consequences. If the head completely snapped off during greasing at pressures of up to 8000psi, the resulting release of grease could cause serious injury.

The internal drilling was very off-centre and the neck wall was very thin and had cracked.

Three further fittings were sectioned, and the drilling was found to be badly off in 2 more of the fittings.

The finish inside some of the fittings was extremely bad, and also of note is the ball lands on these parts are very thin or non-existent