IL capacity A meet ogni need

Le nostre attrezzature e macchinari

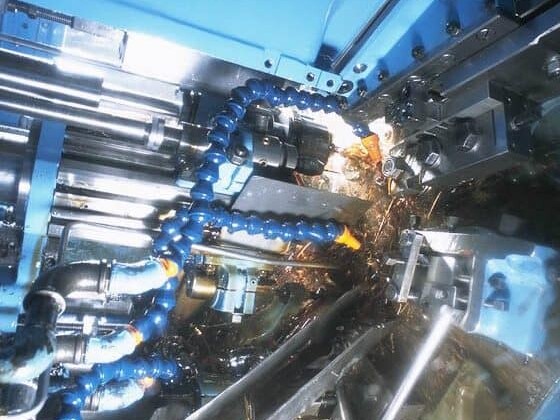

Our Leeds factory is fully equipped to handle every stage of the production process.

From prototype design and testing through to efficient and timely despatch, here is a comprehensive list of the equipment and machinery we currently have in use.

⸻ Leader mondiale nei raccordi per grasso

Turning

- 1- Hardinge GS51 - CNC Lathe

- 1- Citizen L20 VIII Sliding head Mill/Turn - 4m bar loader.

- 1 - Miyano BNJ 42 S 6 axis with live tooling CNC - Fanuc control - Iemca Boss 545 3m bar loader.

- 1 - Hardinge Cobra 42 CNC - Fanuc control - 1.5m Hydrafeed bar loader also with a mini magazine loader attached.

- 1 - Harrison M300 1000mm bed centre lathe with digital readout.

- 1 - Harrison M300 650mm bed centre lathe with digital readout.

Multi-spindle

- 4 - 1" Alfred Herbert 6 spindle BRANs.

- 4 - 1" Alfred Herbert converted to direct electronic drive with Pietro Cucchi bar loader.

- 30 - 7/16" Acme Gridley 6 spindle converted to Direct Electronic drive.

Milling

- 2 - Bridgeport XY CNC milling machines.

- 1 - XYZ CNC milling machine.

Grinding

- 2 - Jones and Shipman 540x digital interface auto dress surface grinders.

- 1 - Jones and Shipman 1300x universal cylindrical grinder with mounted Diaform and digital interface.

- 1 - Jones and Shipman 1311 cylindrical grinder.

Drilling

- 6 - Rotary drilling (3 with tapping).

- 1 - Radial arm driller.

- 2 - Floor mounted drillers.

- 2 - Bench mounted drillers.

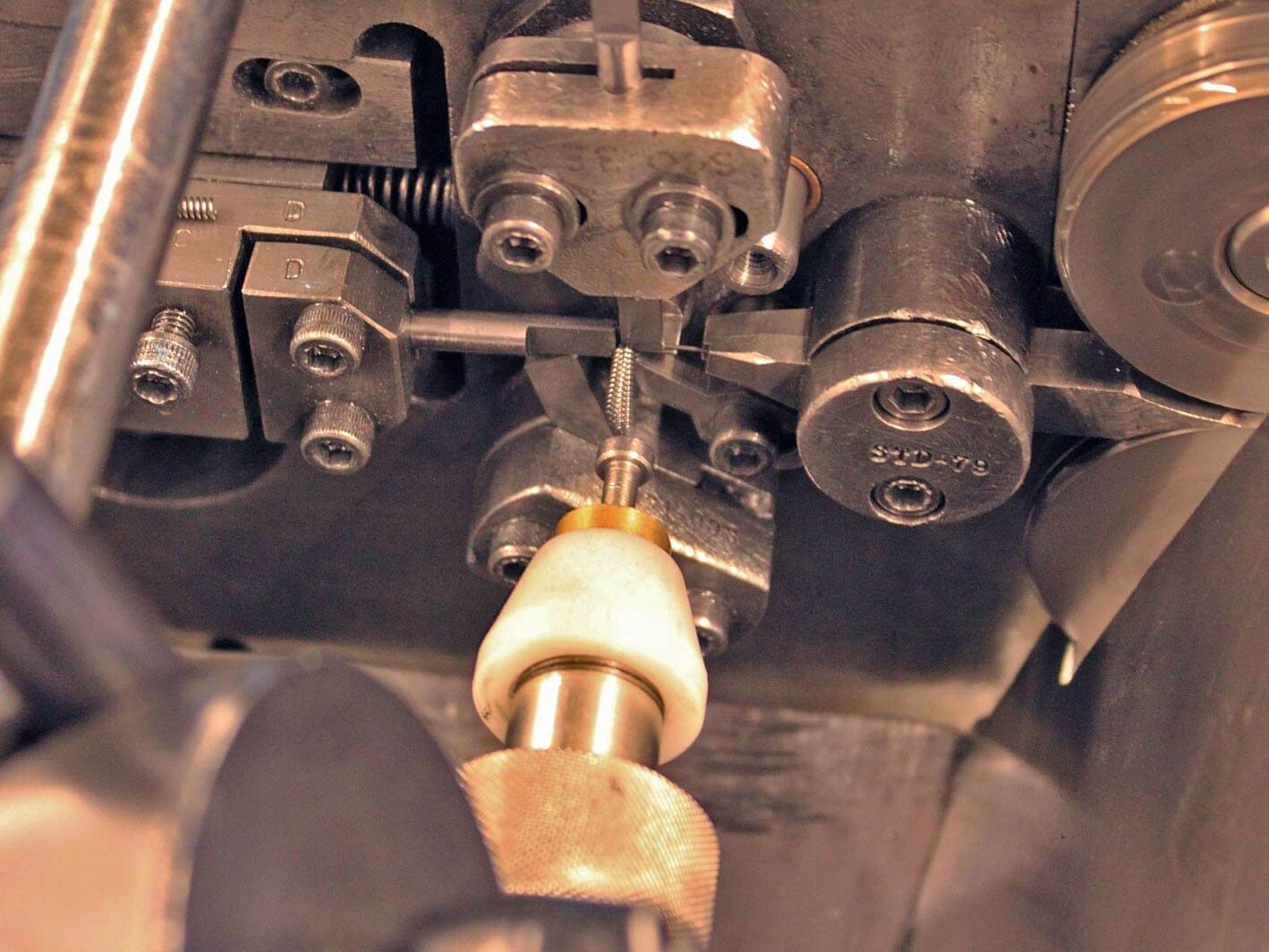

Tapping

- 1 - Microtap G8

- 1 - Microtap - fully automatic with bowl and hopper

- 1 - Maxion G16 - fully automatic with bowl and hopper

Presses

- 6 - 7.5T 8 station hydraulic rotary Hare presses.

- 1 - 7.6T single station hydraulic Hare press.

Spring Making

- 8 - Bennett Mahler single point spring machines with digital speed control powered spool and auto pitch control.

Assembly

- 15 - Fully automatic 8 station rotary transfer assembly machines

- 2 - Semi-automatic 8 station rotary assembly machines

- 2 - 8 station automatic angle assembly machines

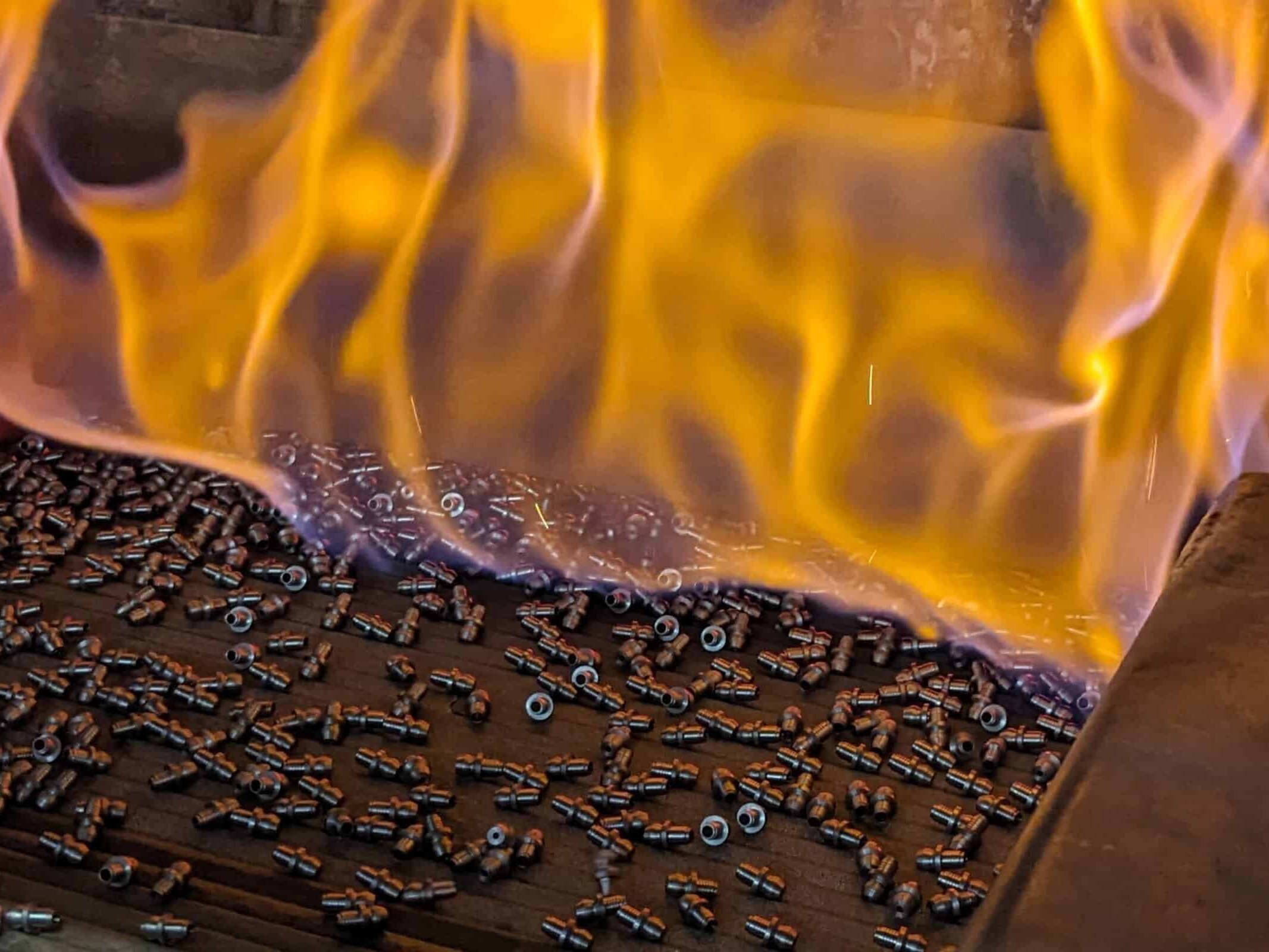

Heat treatment

- 1 - 18" twin shaker hearth - radiant tube with endothermic generator.

- Dew point control - recording facility during processing.

- The furnace has been used only for carbo-nitriding to a shallow case depth

- 1 - Annealing oven (tool room).

- 1 - JN continuous electric stress relieving oven (springs).

Quality Control

- A fully-equipped heat treatment QC control room with fully calibrated light load Vickers and Rockwell hardness testers.

- 1 - Wilson Rockwell hardness tester series 500 with 15, 30 and 45 N and T capability.

- 1 - Zwick Roell Vickers hardness tester with 1, 2.5, 5, 10, 20, and 30Kg loads fully computer integrated for analysis.

- 1 - Sigma HF600 optical projector with profile and front projection.

- 1 - Baty R11 XL optical projector with profile and front projection.

- 2 - Baty R14 XL optical projector with profile projection.

- 1 - Starrett HE400 optical projector with profile projection.

- Calibrated measuring equipment including micrometres, thread gauges etc.

Mechanical Handling

- 1 - 2T BT fourway reach truck

- 1 - Long (4m) pallet truck for steel handling

- 3 - 600kg Pedestrian counter-balance fork-lift (modified for Kingfisher)

- 1 - 1.5T Pedestrian counter-balance fork-truck

- 1 - 2T Counter balance

- 3 - Electric pallet trucks

- 3 - Tipping devices (washing, hardening, swarf handling)

- 1 - Wire spool mobile lifting device

- 1 - Pallet loader for 150Kg export cartons

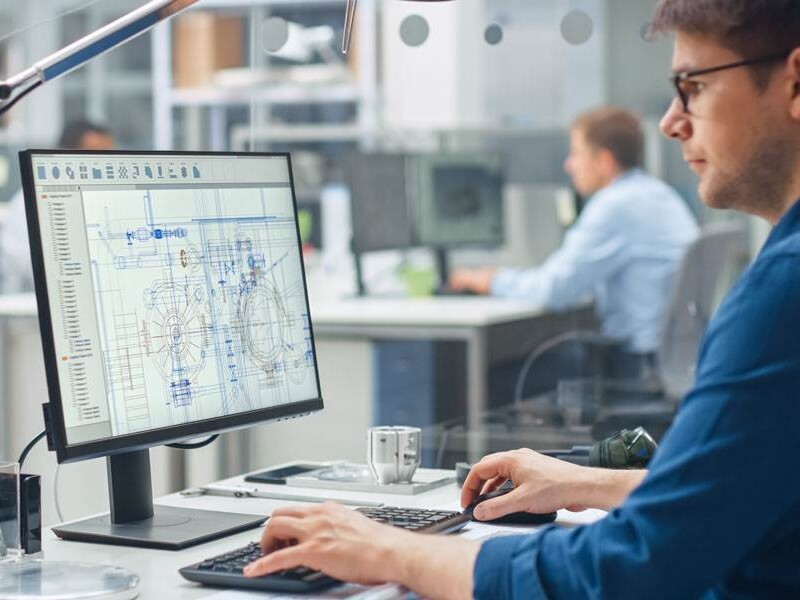

Altri

- Neutral pH Washing machine with horizontal Archimedean screw feed and in built dryer.

- CAD drawing facility.

- Fully equipped toolroom for research and development of machinery and processes.

- Fully equipped maintenance area comprising of centre lathes, vertical milling machine and surface grinder etc.

- Slotting machine.

- Startrite 20RWH vertical band saw.

- Utting UB254 horizontal band saw.

- Drill and tool grinding facilities.

View the full range of products made using our specialist equipment and machinery Qui.